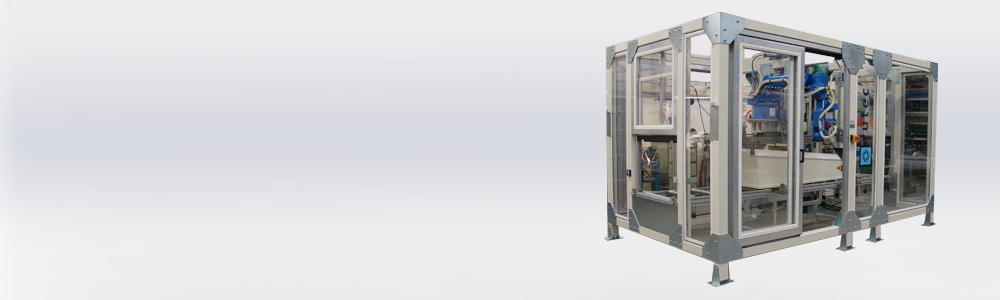

Robot cell

Rutec developed a universal modular solution for flexible automation in virtually every manufacturing environment.

Many business owners know the problem: at the moment a special production machine is constructed, its often only suitable for the purposes for which it was designed. That often requires a heavy investment, that only with this single application to recoup. That is no objection if one can be sure the machine will be used sufficiently on a large scale. But usually in practise it is otherwise, now many manufacturers have to cope with the demand for more variety and smaller production series.

The basic concept is ingenious, with which in almost every production environment a far-reaching automation can be achieved. By cleverly using the abilities and programming facilities of the robot, this completely independent working unit can be used in all kinds of applications for a wide range of manufacturing, Assembly and packaging commands.

The enormous flexibility which is provided makes it possible to complete and establish an automation solution within a short period of time and with relatively small development costs. If changes need to be made in the production process, with this installation it should be quickly possible without having to engage in many procedures. It is also often crucial that the heart, the robot, always will keep a high residual value, because even in a totally different application you can use it again.

An important advantage of the robot-designed arrangement by Rutec , is that it is fully scalable. Without detracting from the basic concept, the dimension is easily adapted to the production environment. Basically, any robot type can be used. The centrally placed robot is accommodated in a solid steel cube frame, made up of standard profiles and surrounded by a standard shielding. The around the robot installed rim equipment consists of universally applicable modules, all of which are good at their task. Each cube is stand alone to use, but also can be easily included in a production line.